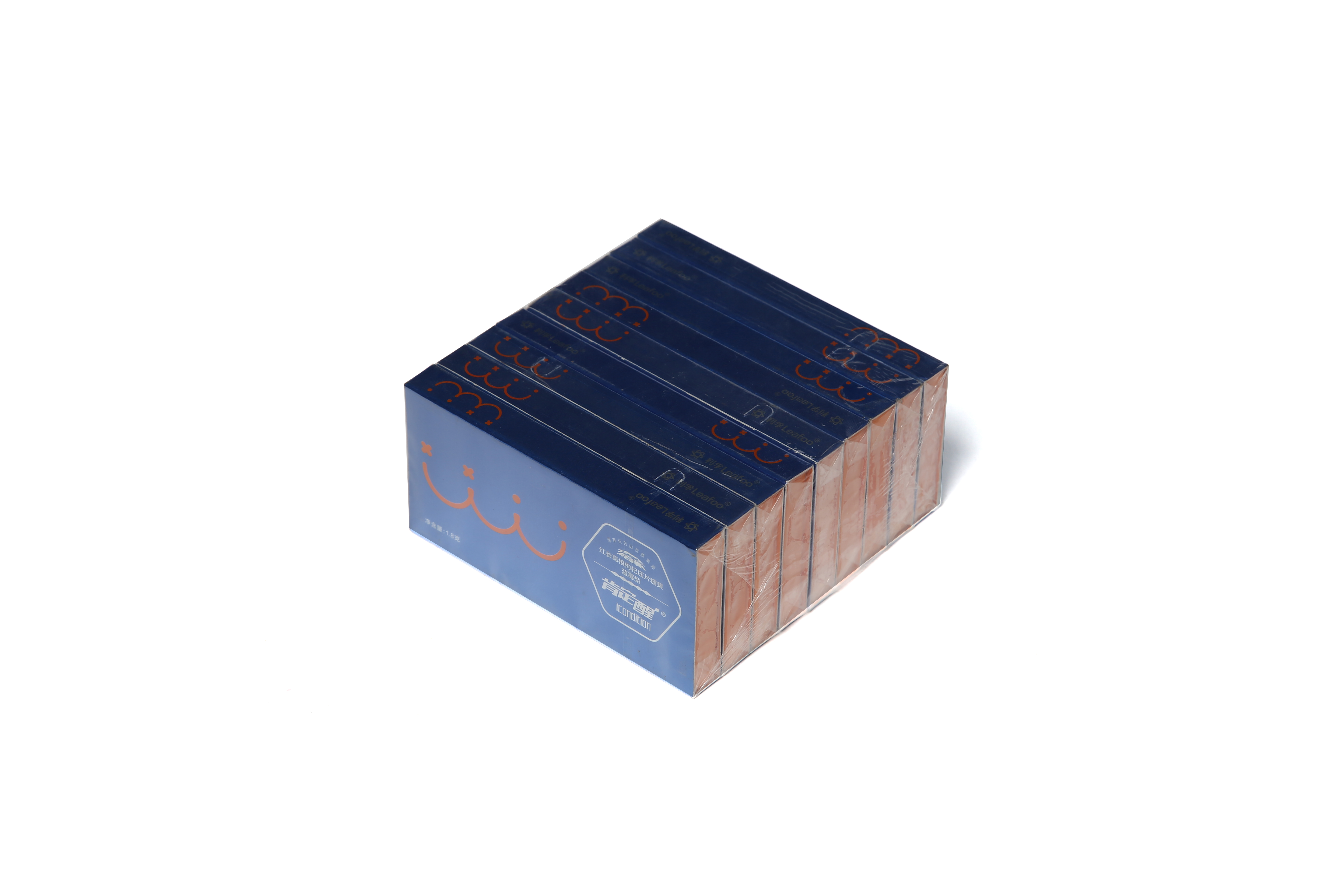

Mechnical High Speed Cellophane Box Wrapping Machine for Perfume box/ tea box/ food box TMP-400S

TMP-400S Mechnical high speed cellophane overwrapping machine can be used for single box or many box packing, the function are Automatic feeding, wrapping, folding, side sealing, end sealing, upper and lower shaping, counting and automatic sticking of anti-counterfeiting wire, as well as surface heating and spot heating etc, making the operation, adjustment, mold replacement and maintenance of the whole machine more convenient and fast.

The machine adopts the design concept of pure mechanical transmission, mainly reflected in the speed up to 40 boxes/min (depending on the size of the package), Stable operation in ormal working, Extremely low failure rate. At the same time, simple operation, quick replacement varieties, convenient maintenance. In case of failure, normal production can be resumed in a short time. The pushing part is driven by sprocket and chain, and the film feeding is controlled by servo motor. The pushing box mechanism is equipped with overload protection device, which reduces the failure rate.

The conveying function can be divided into linear (180 degrees) or vertical (90 degrees) conveying. This is mainly used for automatic packaging of single or multiple pieces (package) of all kinds of boxes in the industries of medicine, food, health products, tea, cosmetic, present stationary, audiovisual products etc. It can replace the box in the paper and also can reduce the packing cost about 95% .Using the machine to pack can defend takeproof moisture and proof dust etc. It improve the productions level , increase the productions additional value .

1. Adopting the man-machine interface , PLC control, Failures diagnosing software .

2. Adopting the servo motor to feed film. The speed and the length can be adjusted .Using the film smooth and length accurate.

3. Adopting full cylinder drive .Steady running .accurately Synchronizing .conveniently adjusting hard sealing.

4. Compact structure .Easy to operation and Manipulating .complete safety device

|

Model |

TMP-400S |

|

Packaging material |

OPP,BOPP , PVC |

|

Production capacity |

10-40 packs/min. |

|

Bag size |

L(50-400)×W(40-220)×H(10-90)mm |

|

Power supply |

AC380V 50Hz, 6.5Kw |

|

Working pressure |

0.6 Mpa |

|

Air consumption |

400L/min. |

|

Weight |

850kg |

|

Overall dimension |

2450×1000×1850mm |

|

Input table dimension |

1500×240×870mm |