Servo Control High Speed Flow Shrink Packaging Machine DZR-590

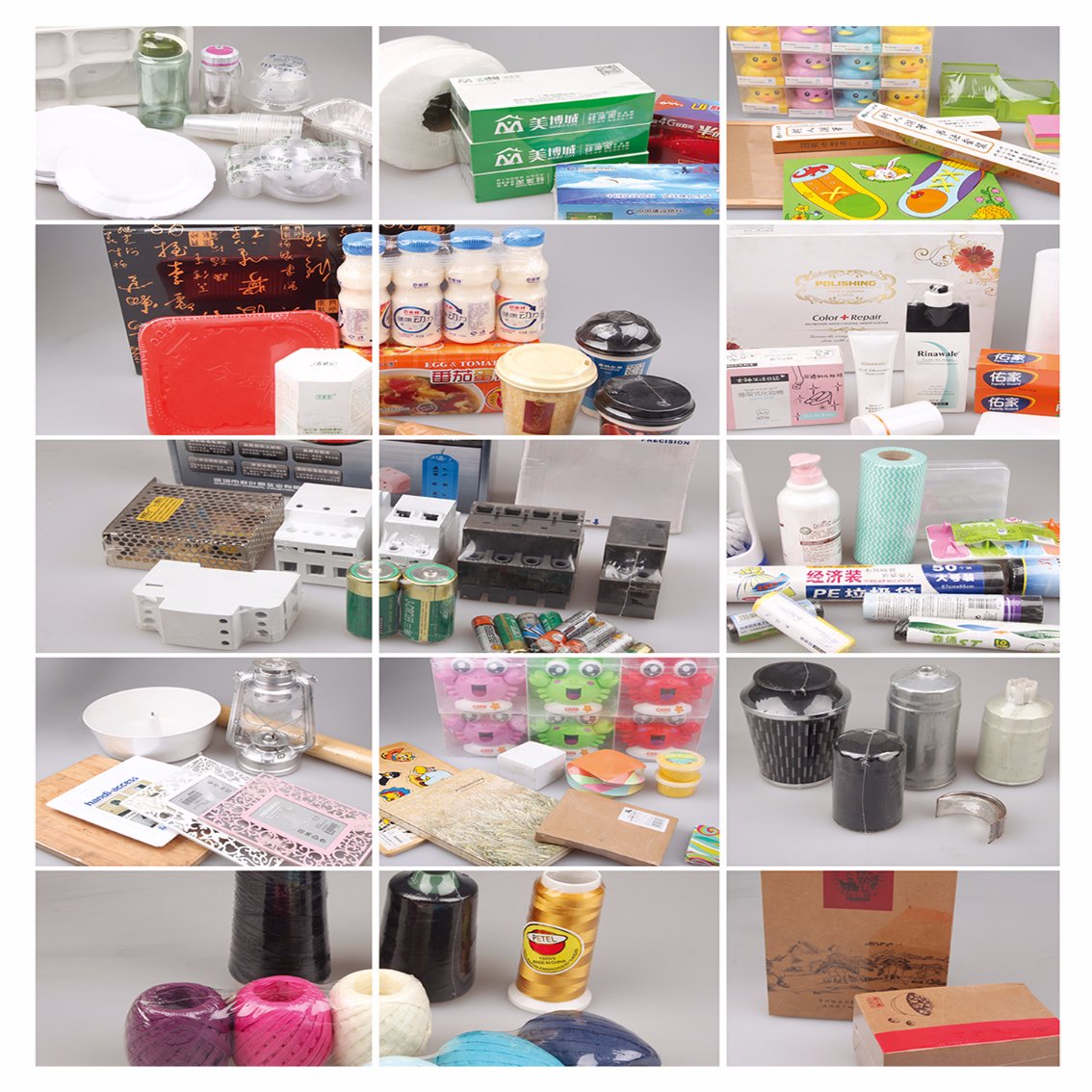

Appliable Scope: Shrink packaging in groups of food, pharmaceuticals and beverages, instant bowl noodles, milk tea cups, mosquito coils, wall paper,filters, electrical switches, batteries,plastic wraps, garbage bags,tissue-paper,kitchen seasoners,various sizes of cartons and boxes, stationeries,pressworks,hardwares, industrial parts, cosmetics and other commodities.

1. Color touch screen control system, driven by three servo motors, easy to operate, high stability, high packaging efficiency and low failure rate; bag length, speed and temperature can be individually adjusted, easy to operate and accurate.

2. Cut-proof safety clutch device,does not damage the packaging.

3. High sensitivity photoelectric eye color standard tracking, mathematically input the sealing position, so as to make the sealing position more accurate.

4. Temperature independent PID control, better suitable for various coating materials.

5. Positioning stop function, no sticking knife, no waste of film.

6. The transmission system is simple, reliable and easy to maintain.

7. Cut the product to be automatically reversed, restart directly after boot convenient operation.

8. Adding refuse recovery device to make the package more beautiful, save about 20% -30% of material compared with traditional folding film packing machine.

9. It is feasible to be equipped with a typewriter or inkjet printer, and it is unnecessary to use manual.

10. It has motor brake control, and the equipment reaction is sensitive.

11. High efficient double temperature zone of heat shrink furnace, high efficient hot air circulation, automatic temperature control, to ensure shrinkage quality.

|

Max Flim size |

≤590mm |

||||||

|

Model |

120 |

150 |

180 |

210 |

240 |

||

|

Packing size |

L :Bag length |

L:60mm-320mm |

L:100mm-450mm |

L:150mm-530mm |

L:180mm-600mm |

L:210mm-650mm |

|

|

W:width |

w:10mm-200mm |

w:10mm-200mm |

w:10mm-200mm |

w:10mm-200mm |

w:10mm-250mm |

||

|

H:height |

H:5mm-35mm |

H:35mm-70mm |

H:65mm-100mm |

H:80mm-130mm |

H:100mm-150mm |

||

|

Packing speed |

30-150(pack / min) |

30-150(pack / min) |

30-135(pack / min)) |

30-100(pack / min) |

30-80(pack / min) |

||

|

Flim type |

PVC;POF |

||||||

|

Power consumption |

Packaging machine:4.75KW;Shrinking machine:13.5KW |

||||||

|

Power supply |

Packaging machine:220V,50HZ/60HZ;Shrinking machine:380V,50HZ/60HZ |

||||||

|

Envelop dimensions |

4800x1170x1500mm |

||||||

|

Shrinking machine |

Dimensions:2600x600x1700mm |

Furnace channel size:2300*250*200mm |

|||||

|

Weight |

Packaging machine:1000KG |

Shrinking machine:600KG |

|||||