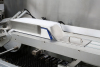

Pharmaceutical Automatic Cartoning Machine Horizontal & Continuous DZH-400

DZH-400 High Speed Automatic Cartoning Machine is a new design type of High speed great station automatic box packing machine.It is suitable for medicine blister ,pillow pack,tube,bottle,ampoule bottle and similar goods. DZH-400 High speed cartoner adopt continuous transmission, synchronization pushing and rotary suction box device,the speed is faster and more smooth,less noise.Use the balcony type pushback layout, operation more convenient and clean up.

Cartoner machine adopt the frequency speed control,PLC control,photoelectric monitoring operation of each station.in case of failure in operation, can automatically stop the machine to show the reason, so as to timely troubleshooting.The performance has reached the leading domestic level, the technology has filled the domestic gap, and compare with the import equipment is more practical and economical,and established a new production mode with automatic production line, which fully reflects its superiority.

1. PLC control,frequency conversion speed regulation,electrical element adopt international famous brand.

2. Adopt HMI operating system, continuous box loading system, and the use of international advanced chain type of new structure, improve the performance of the product production efficiency.

3. Equipped with domestic advanced origami machine, paper output speed is fast and stable, easy to operate.

4. The product adopts a rotating box opening method with multiple suction heads, and the box is put into the box packing machine chain and grid belt accurately.

5. The material pushing method adopts the structure of rear feeding type and multi-pushing

|

Model |

DZH-400 |

|

|

Production capacity |

30-400 box/min |

|

|

Box |

Quality requirements |

300-350g/㎡(depends on the size of the carton) |

|

Range of size (L×W×H) |

(70-200)mm×(25-84)mm×(15-70)mm |

|

|

Leaflet |

Quality requirements |

60-70g/㎡ |

|

Unfold leaflet size (L×W) |

(100-260)㎜×(90-160)㎜ |

|

|

Folded leaflet size (1-4)(L×W) |

(100-260)㎜×(20-40)㎜ |

|

|

Air pressure

|

Pressure |

0.5-0.7mpa |

|

Consumption |

700-900L/min |

|

|

Air Consumption |

380V 50HZ |

|

|

Main motor power |

4.0kw |

|

|

Outline demesion(L×W×H) |

4550㎜×1600㎜×1700㎜ |

|

|

Weight |

About 5000kg |

|